|

|

|

|

|

|

|

SMA Series |

|

|

|

|

SMA connectors are based on MIL-C-39012 specifications and provide a constant 50 Ohm characteristic impedance up to 12.4 GHz. The SMA product designs include a wide range of configurations and will consider each customer's special requirements. The major application of SMA series connectors are test & measurement, mobile communication & other devices.

|

|

|

|

|

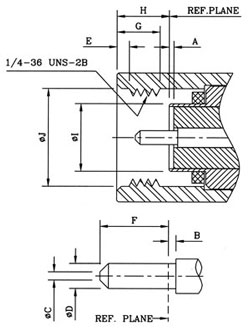

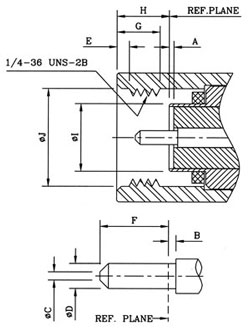

Plug interface

|

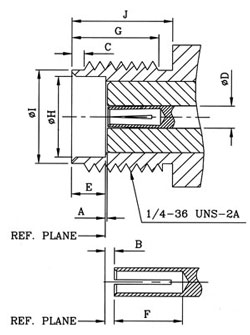

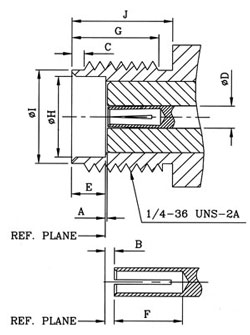

Jack interface

|

|

|

|

|

|

Item

|

Plug interface dimensions in mm

|

|

min

|

max

|

|

A

|

0.00

|

0.25

|

|

B

|

0.00

|

0.25

|

|

C

|

-

|

0.30

|

|

D

|

0.90

|

0.94

|

|

E

|

0.38

|

1.14

|

|

F

|

-

|

2.54

|

|

G

|

3.30

|

-

|

|

H

|

-

|

3.43

|

|

I

|

-

|

4.59

|

|

J

|

6.35

|

-

|

|

|

|

Item

|

Jack interface dimensions in mm

|

|

min

|

max

|

|

A

|

0.00

|

0.25

|

|

B

|

0.00

|

0.25

|

|

C

|

0.38

|

1.14

|

|

D

|

1.24

|

1.29

|

|

E

|

1.88

|

1.98

|

|

F

|

2.67

|

-

|

|

G

|

4.32

|

-

|

|

H

|

4.60

|

-

|

|

I

|

5.28

|

5.49

|

|

J

|

5.54

|

-

|

|

|

|

|

|

|

|

Material

|

|

Body, coupling nut

|

Brass, gold or nickel plated

|

|

Center contact

|

Brass (male)/BeCu (female), gold plated

|

|

Insulator

|

Teflon

|

|

Crimp ferrule

|

Annealed copper, gold or nickel plated

|

|

Gasket

|

Silicone rubber

|

|

Electrical

|

|

Impedance

|

50 Ohm

|

|

Frequency range

|

0 ~ 12.4 GHz

|

|

Working voltage

|

RG178 = 170V rms, RG58 = 335V rms, RG174, 188, 316 = 250V rms max @sea level

|

|

Insulator resistance

|

5000 MOhm min

|

|

Dielectric withstanding voltage

|

RG178 = 500V rms, RG58 = 1000V rms, RG174, 188, 316 = 750V rms min

|

|

Contact resistance

|

Center contact: 3.0 mOhm max

Outer contact: 2.0 mOhm max

|

|

VSWR

|

Straight connector:

RG178 = 1.20 + 0.025F (F in GHz)

RG174, 188, 316 = 1.15 + 0.02F (F in GHz)

RG58 = 1.15 + 0.01F (F in GHz)

Right angled connector:

RG178 = 1.20 + 0.03F (F in GHz)

RG174, 188, 316 = 1.15 + 0.03F (F in GHz)

RG58 = 1.15 + 0.02F (F in GHz)

|

|

Insertion loss

|

Straight connector = 0.06 x (f) GHz. Test frequency @6 GHz

Right angled connector = 0.15 x (f) GHz. Test frequency @6 GHz

|

|

Mechanical

|

|

Force to engage

|

The torque required to engage and disengage shall not to exceed 2 in/lbs

|

|

Coupling nut retention force

|

60 lbs min (for plugs only)

|

|

Coupling proof torque

|

15 in/lbs min

|

|

Connector durability

|

500 matings

|

|

Cable retention force

|

RG178 = 7.3 lbs min, RG316 = 12.1 lbs min, RG 58 = 28.7 lbs.min

|

|

Environmental

|

|

Corrosion (Sail spray)

|

MIL-SID-202F, Method 101D, Condition B

|

|

Thermal shock

|

MIL-STD-202F, Method 1017G, Condition A

|

|

Vibration

|

MIL-STD-202F, Method 204D, Condition B

|

|

Mechanical shock

|

MIL-STD-202F, Method 213B, Condition A

|

|

|

|

|

|

|

Alpha Center

351 Irving Drive, Oxnard, CA 93030, USA

|

|

“©2021 Alpha Products, Inc. All rights reserved.

|

|

|